Capella Vision Powered Dimensioning and Weighing System

Request a Quote

Please complete the form below and we will be in touch with you shortly.

Product Features

Product Types

Product Specifications

| TYPE | MINI |

|---|---|

| WEIGHT CAPTURE | Static |

| BARCODE CAPTURE | Semi Auto / Auto – Topside |

| INDUCT | Direct / Conveyor Based / Stand Alone Carriage Based / Dual Induct Based |

| SPECIFICATIONS | Length: 50 mm – 600 mm Width: 50 mm – 600 mm Height: 10 mm – 600 mm Weight: 50 gms – 25 kgs Weighing Accuracy: +/- 0.020 kg (20 gms) or .05% whichever is more Weighing Increment: 10 gm Dimension Accuracy: +/-10 mm (5 mm for height) |

| THROUGHPUT (PPH) | 600 – 3000 |

| TECH ACCESSORIES | PLC & HMI Included (except Direct Induct), Computer & server can be provided by client |

| IMAGE CAPTURE | Optional with a separate camera* |

| TYPE | MINI |

|---|---|

| WEIGHT CAPTURE | In-motion |

| BARCODE CAPTURE | Auto – Topside / Auto – 3 side scan / Auto – 5 side scan |

| INDUCT | Conveyor Based |

| SPECIFICATIONS | Length: 50 mm – 600 mm Width: 50 mm – 600 mm Height: 10 mm – 600 mm Weight: 50 gms – 25 kgs Weighing Accuracy: +/- 0.020 kg (20 gms) or .05% whichever is more Weighing Increment: 10 gm Dimension Accuracy: +/-10 mm (5 mm for height) |

| THROUGHPUT (PPH) | 3000 |

| TECH ACCESSORIES | PLC & HMI Included (except Direct Induct), Computer & server can be provided by client |

| IMAGE CAPTURE | Optional with a separate camera* |

| TYPE | MIDI |

|---|---|

| WEIGHT CAPTURE | Static |

| BARCODE CAPTURE | Semi Auto / Auto – Topside |

| INDUCT | Gravity Conveyor Based / Powerized Conveyor Based |

| SPECIFICATIONS | Length: 100 mm – 1000 mm Width: 100 mm – 1000 mm Height: 100 mm – 1000 mm Weight: 400 gms – 150 kgs Weighing Accuracy: +/- 0.100 kg (100 gms) or .05% whichever is more Weighing Increment: 50 gms Dimension Accuracy: +/-50mm |

| THROUGHPUT (PPH) | 400-1200 |

| TECH ACCESSORIES | PLC & HMI Included (except gravity conveyor based), Computer & server can be provided by client |

| IMAGE CAPTURE | Optional with a separate camera* |

| TYPE | MIDI |

|---|---|

| WEIGHT CAPTURE | In-motion |

| BARCODE CAPTURE | Auto – Topside / Auto – 3 side scan / Auto – 5 side scan |

| INDUCT | Belt Conveyor Based / TBC Based |

| SPECIFICATIONS | Length: 100 mm – 1000 mm Width: 100 mm – 1000 mm Height: 100 mm – 1000 mm Weight: 400 gms – 150 kgs Weighing Accuracy: +/- 0.100 kg (100 gms) or .05% whichever is more Weighing Increment: 50 gms Dimension Accuracy: +/-50mm |

| THROUGHPUT (PPH) | 1200 |

| TECH ACCESSORIES | PLC & HMI Included (except gravity conveyor based), Computer & server can be provided by client |

| IMAGE CAPTURE | Optional with a separate camera* |

| TYPE | MAXI |

|---|---|

| WEIGHT CAPTURE | Static |

| BARCODE CAPTURE | Semi Auto / Auto – Topside |

| INDUCT | Direct |

| SPECIFICATIONS | Length: 200 mm – 1500 mm Width: 200 mm – 1500 mm Height: 200 mm – 1000 mm Weight: 10kgs – 3000 kgs Weighing Accuracy: +/- 0.200 kg (200 gms) or .05% whichever is more Weighing Increment: 100gms Dimension Accuracy: ± 100 mm |

| THROUGHPUT (PPH) | 300 |

| TECH ACCESSORIES | Computer & server can be provided by client |

| IMAGE CAPTURE | Optional with a separate camera* |

Why You Need CAPELLA?

Our CAPELLA DWS System will help you:

APPLICATION

PARCEL SHIPPING

Incorporating dimensioning and weighing system into your warehouse shipping stations will save you money on parcel shipping costs, improve your manifesting efforts, and assist you in revenue recovery.

SPACE OPTIMIZATION

The package data provided by a dimensioning and weighing system can optimize your operation, leading to improved order fulfillment, carton selection, slotting projects, and overall warehouse efficiency.

WAREHOUSING & DISTRIBUTION

The data obtained from the system can be utilized for storage location selection, carton selection & shipment planning. By interfacing directly with the manifesting or WMS applications, it helps in data storage, transfer and validation when required.

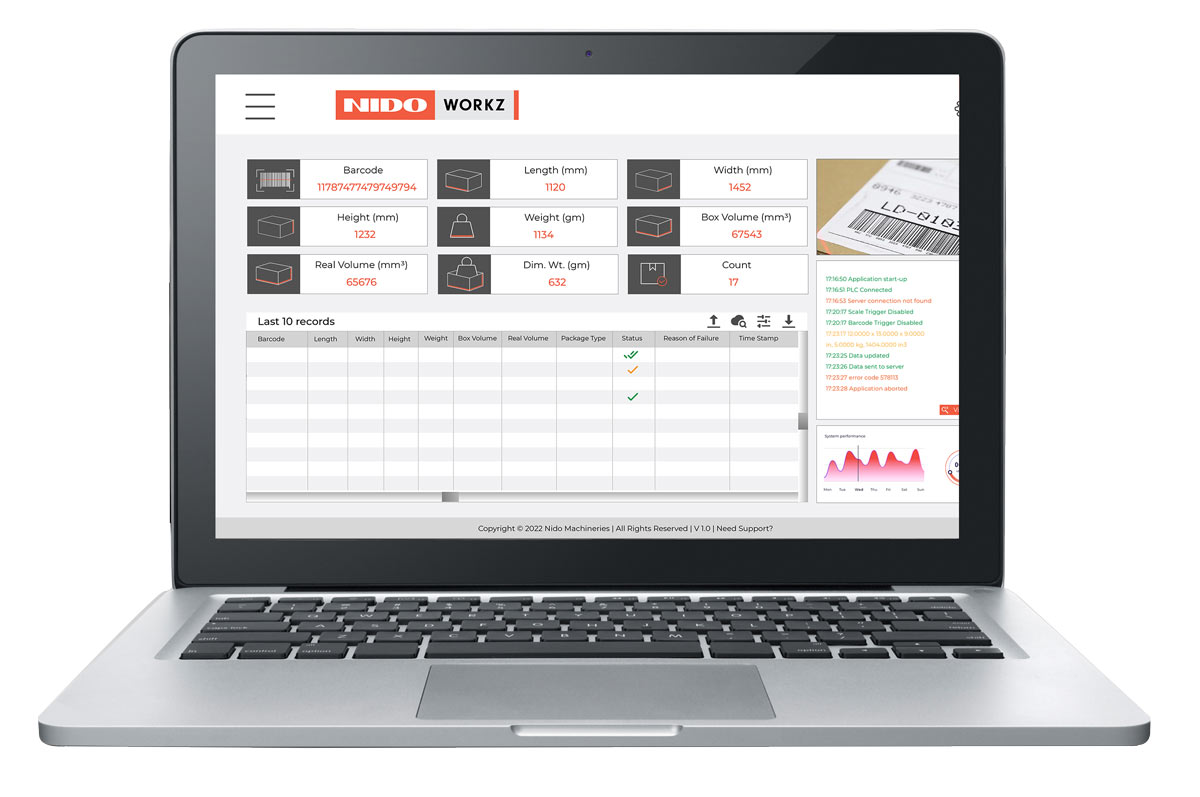

DWSCONTROL SOFTWARE APPLICATION

NidoWorkz’s DWSControl is our proprietary modular software suite that collects the data from the machine and allows you to format, store, validate, utilize and transfer it as needed. With a varieties of communication modules and integration option, it can smoothly sync with the existing ERP application creating an ecosystem where the hardware and software can communicate to deliver faster and accurate results.

- Software with user friendly interface to gather, validate and transfer data to many types of host systems and databases.

- Direct interface with WMS / ERP / Shipping application via API, ODBC.

- Custom import / export features, allowing data to be easily imported or exported into the majority of the warehousing and shipping software solutions.

- Data transfer on real time / batch mode / FTP basis.

- Integration with digital camera to capture images with each measurement.

- Can be integrated with Capella Conveyors and Deneb Sorters for seamless operations.

- Can be customized as per your requirements.