Carriage based Profiling, Sorting & Fulfillment System

One Ecosystem. Endless Possibilities.

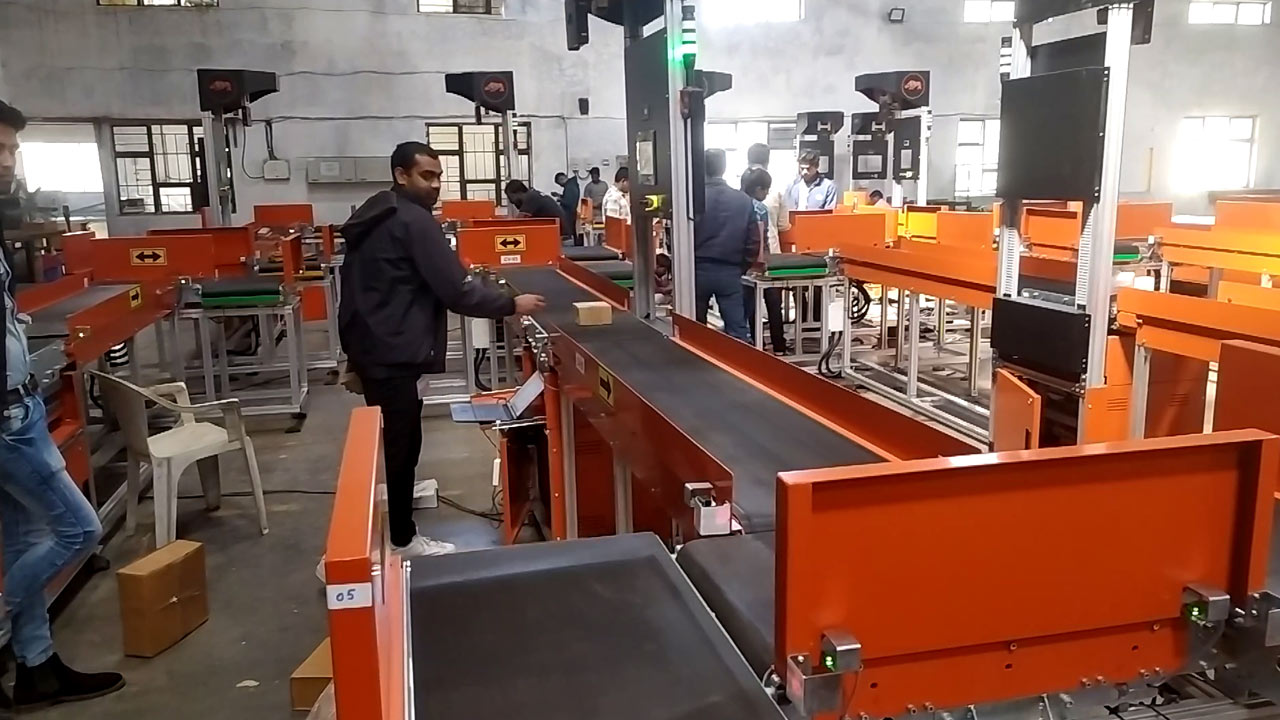

AUTOMATION CHALLENGES TODAY…

No ‘single’ Solution Available

There is no ‘single’ solution available in the market which provides flexibility to adapt to advancing scales of businesses and industries

Complex & Capex Intensive

Current entry level automation solutions are too complex to maintain and CapEx intensive, making it impossible for early stage companies to adapt to automation

No Option To Scale Up as per Requirement

There is no system in the market that can help customers scale up the same solution with time as per their needs

Need To Streamline Process

Rising need for a profiling cum sorting cum fulfilment solution to streamline the order handling process

Expensive

Perception of automation as a complex and expensive process

Limitations For Small & Mid Level Business

Limited availability of entry level automation for small to mid level business houses

Warehouses try to tackle challenges either with the help of manual operations or complex large scale automation currently available. These come with their own set of challenges.

Most importantly companies today are growing and

they need a solution that grows with them. They need a modular, scalable and easy to deploy automation solution.

We at NIDO Automation have been aware of these issues and have been researching and developing a solution that addresses ALL these challenges in the smartest and most practical manner.

The solution has to be a product that is... ScalableModularEasy to deployLow maintenance costMinimal power consumptionQuick ROICompact footprintIntelligent data driven systemSuited for small to mid size operations

Should ‘GROW’ along with the customers’ operations.

Our Inspiration – Building Blocks

It is a simple system with infinite potential. imagine if we could create a system that operates like building blocks with base pieces that enable assembly, disassembly, and repurposing into new configurations. This adaptable approach could revolutionize scalability and flexibility, allowing for seamless expansion and optimization as needed.

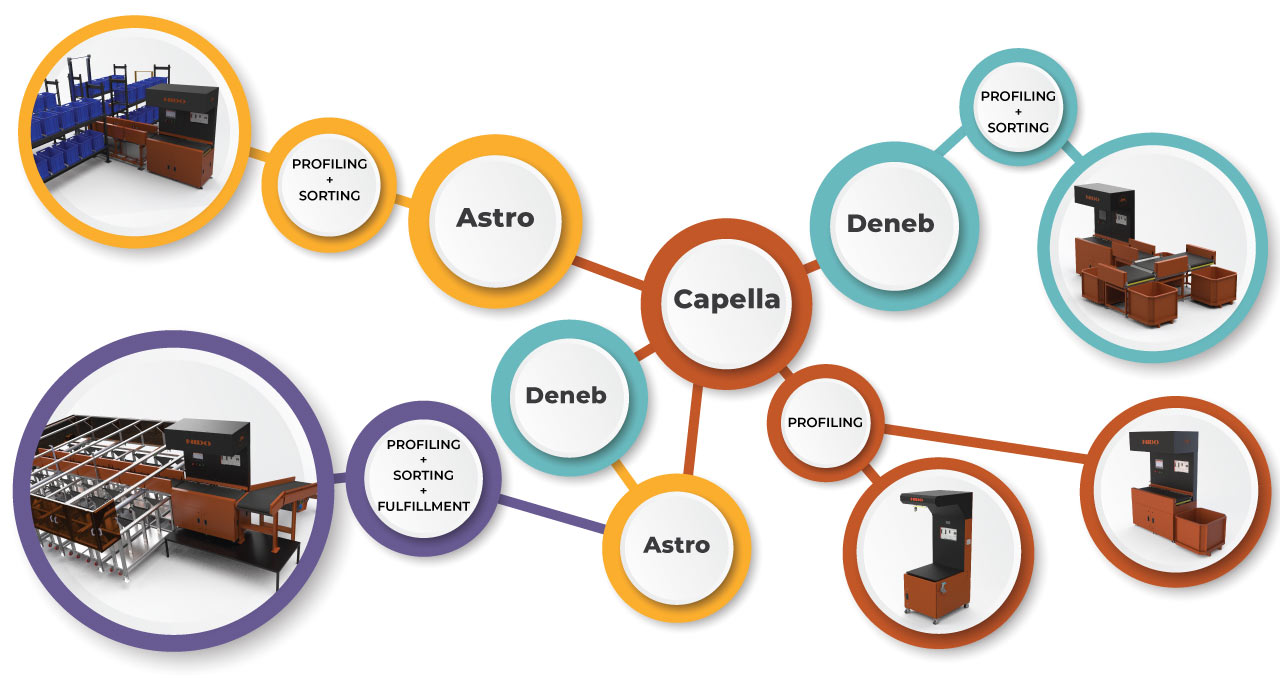

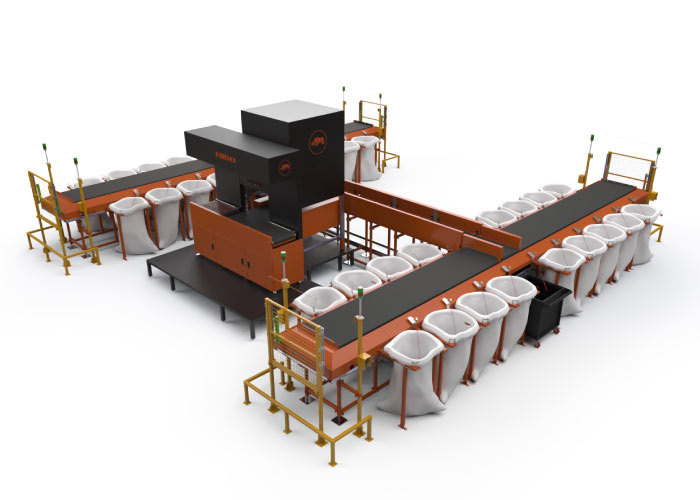

Introducing Carriage Based Profiling, Sorting & Fulfillment

The ACD Ecosystem

|

|

|

|---|---|---|

| Package Type: Flyers, Carton Boxes, Shrink wrapped boxes, strapped boxes, polythene wrapped parcels, jiffys |

Package Type: Flyers, Carton Boxes, Shrink wrapped boxes, strapped boxes, polythene wrapped parcels, jiffys |

Package Type: Flyers, Carton Boxes, Shrink wrapped boxes, strapped boxes, polythene wrapped parcels, jiffys |

| Package Size: 100 x 100 x 10 mm to 1000 x 800 x 800 mm |

Package Size: 100 x 100 x 10 mm to 500 x 400 x 300 mm |

Package Size: 100 x 100 x 10 mm to 500 x 400 x 300 mm |

| Package Weight: 50 gms to 80 kgs |

Package Weight: 50 gms to 5 kgs |

Package Weight: 50 gms to 5 kgs |

| Throughput: Upto 2800 pph |

Throughput: Upto 5500 pph |

Throughput: Upto 2200 pph |

| Not Applicable | Sort Locations: 16 Destinations per system* |

Sort Locations: 250, The destination count depends upon Chute placement (e.g: with gaps for bag retrieval, no of tiers in solution) and throughput required per ASTRO* |

*Modularity allows multiple Denebs or Astros to be clubbed to make a solution that fits your needs

The ACD Eco-System that can ‘Grow as you Grow’

consumption

Modular

and Scalable

Omnichannel

Fulfillment

Our Carriage Based Ecosystem Coverage