Grid Based Sorting

& Fulfillment System

AUTOMATION CHALLENGES TODAY…

No ‘single’ Solution Available

There is no ‘single’ solution available in the market which provides flexibility to adapt to advancing scales of businesses and industries

Complex & Capex Intensive

Current entry level automation solutions are too complex to maintain and CapEx intensive, making it impossible for early stage companies to adapt to automation

No Option To Scale Up as per Requirement

There is no system in the market that can help customers scale up the same solution with time as per their needs

Need To Streamline Process

Rising need for a profiling cum sorting cum fulfilment solution to streamline the order handling process

Expensive

Perception of automation as a complex and expensive process

Limitations For Small & Mid Level Business

Limited availability of entry level automation for small to mid level business houses

Warehouses try to tackle challenges either with the help of manual operations or complex large scale automation currently available. These come with their own set of challenges.

Most importantly companies today are growing and

they need a solution that grows with them. They need a modular, scalable and easy to deploy automation solution.

We at NIDO Automation have been aware of these issues and have been researching and developing a solution that addresses ALL these challenges in the smartest and most practical manner.

The solution has to be a product that is... ScalableModularEasy to deployLow maintenance costMinimal power consumptionQuick ROICompact footprintIntelligent data driven systemSuited for small to mid size operations

Should ‘GROW’ along with the customers’ operations.

Our Inspiration – Building Blocks

It is a simple system with infinite potential. imagine if we could create a system that operates like building blocks with base pieces that enable assembly, disassembly, and repurposing into new configurations. This adaptable approach could revolutionize scalability and flexibility, allowing for seamless expansion and optimization as needed.

Witness how a simple belt carriage can be innovatively utilized to transform the manner in which intralogistics automation takes place. The canvas of your warehouse can be brought to life with endless possibilities.

Say Hello to Simple.

Say Hello to Non Conventional.

Say Hello to Automation that grows as you grow.

Say Hello to Automation TODAY.

Say Hello to ASTRO.

A Revolutionary

System with

ENDLESS POSSIBILITIES

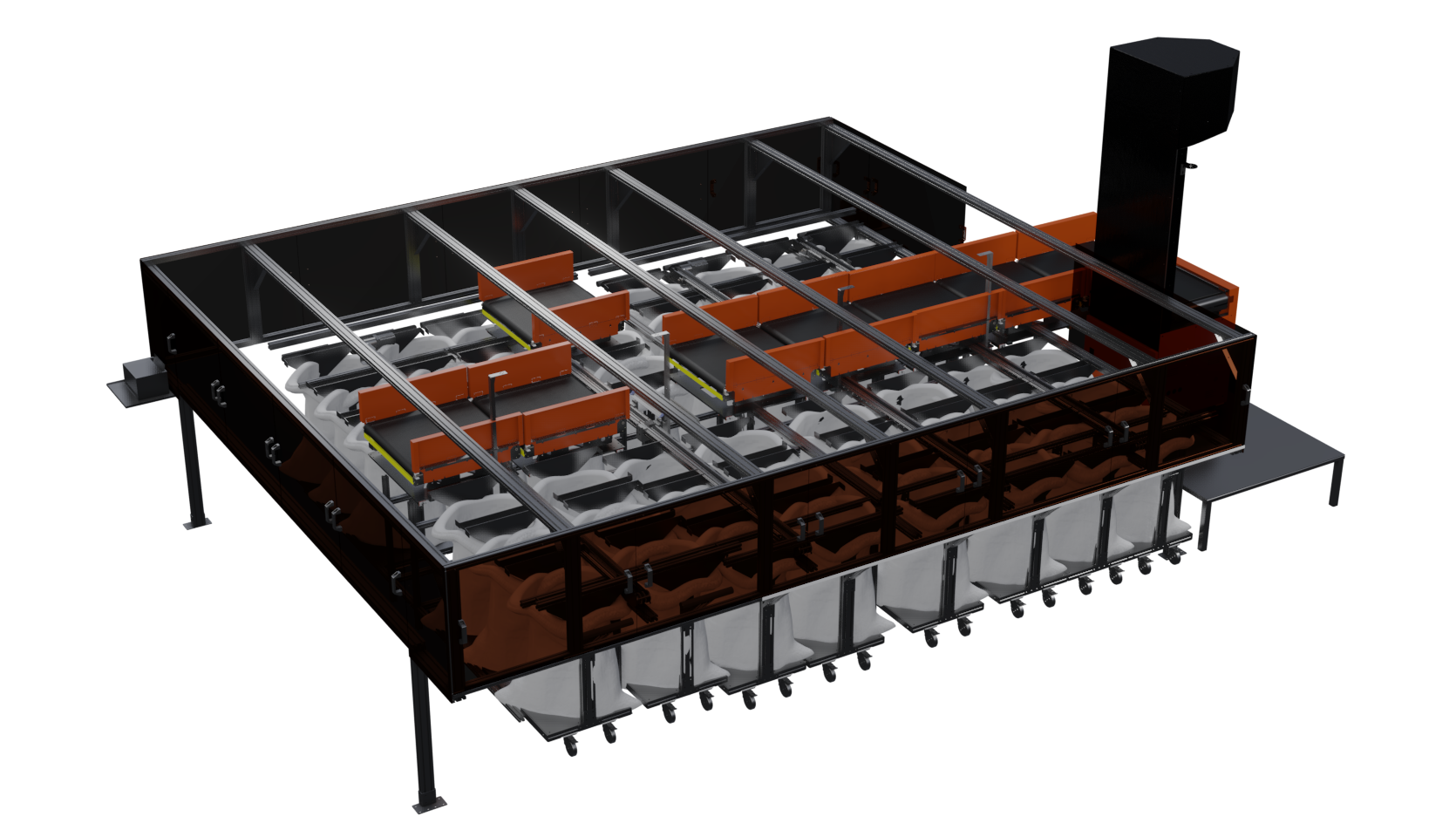

ASTRO Grid Based Sorting and Fulfillment System

PRODUCT HIGHLIGHTS

| Package Type: | Flyers, Carton Boxes, Shrink wrapped boxes, strapped boxes, polythene wrapped parcels, jiffys |

|---|---|

| Package Size: | 100 x 100 x 10 mm to 500 x 400 x 300 mm |

| Package Weight: | 50 gms to 5 kgs |

| Throughput: | Upto 2200 pph |

| Sort Locations: | 250, The destination count depends upon Chute placement (e.g: with gaps for bag retrieval, no of tiers in solution) and throughput required per ASTRO* |

*Modularity allows multiple Denebs or Astros to be clubbed to make a solution that fits your needs

WATCH ASTRO IN ACTION

Meet ASTRO

ASTRO Solutions

ASTRO For Express Parcel Industry

ASTRO for Apparel Industry

ASTROSort H - H

ASTROSort H - Cube

ASTROSort V - T

ASTRO Sort H - H

ASTROinduct is a highly versatile system to cater the modern requirements. It can cater to any type of conveyable shipment or bag and can be combined with profiling (weighing, dimensioning & barcode scanning) of the shipments.

ASTROinduct is a highly versatile system to cater the modern requirements. It can cater to any type of conveyable shipment or bag and can be combined with profiling (weighing, dimensioning & barcode scanning) of the shipments.

There are multiple options possible as per the application such as Single induct, dual induct, parallel induct, in-line induct, etc.

ASTROcart is a humble belt carriage used to hold and convey shipments. There are 3 main types of ASTROcarts that form the base of the building block. Basis the type of application and the solution designed, the correct ASTROcart placed in the optimal orientation, works its magic to bring the ASTRO EcoSystem to life.

ASTROcart is a humble belt carriage used to hold and convey shipments. There are 3 main types of ASTROcarts that form the base of the building block. Basis the type of application and the solution designed, the correct ASTROcart placed in the optimal orientation, works its magic to bring the ASTRO EcoSystem to life.

These specially designed carts can either run independently or in unison with multiple other carts depending on the type of shipment is needs to convey.

ASTROtrack is a simple, yet innovative set of hardware which acts as the glue and binds all the other components of the ASTRO EcoSystem together. These are servo driven tracks that move the ASTROcart horizontally or vertically to the relevant position.

ASTROtrack is a simple, yet innovative set of hardware which acts as the glue and binds all the other components of the ASTRO EcoSystem together. These are servo driven tracks that move the ASTROcart horizontally or vertically to the relevant position.

The length, the height and the orientation of these tracks can be selected as per the layout. They are specially designed to be low maintenance and high speed, and at the same time have precise positioning for sorting accuracy.

ASTROcollect is the wide range of options that can be utilized for the collection of shipments which move on the ASTROcart and the ASTROtrack. Depending on the shipment type and the designed solution which is specially designed with intelligent features.

ASTROcollect is the wide range of options that can be utilized for the collection of shipments which move on the ASTROcart and the ASTROtrack. Depending on the shipment type and the designed solution which is specially designed with intelligent features.

ASTROcollect options include bag holders, bins, cages, single or multi level chutes, single bag trolleys, conveyors, multi bag trolleys, , pigeon holes, rack trolleys, tote holders, etc.

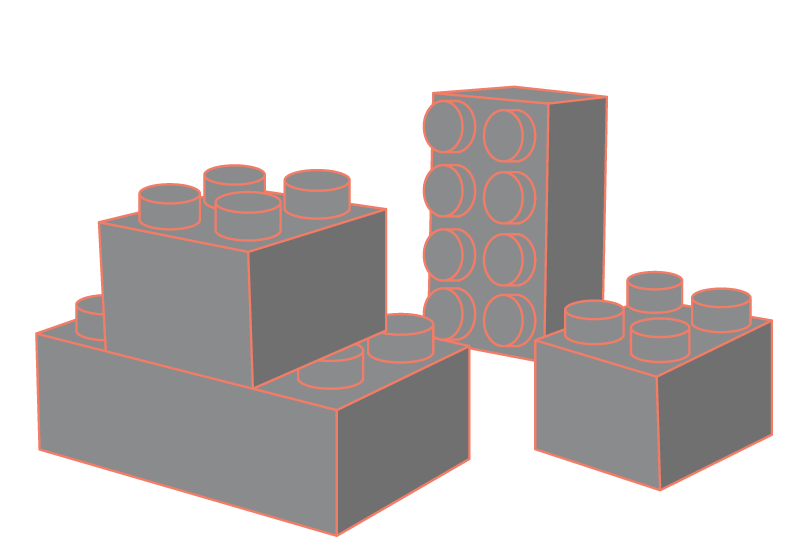

ASTROtech is the brain behind the entire solution. It is essentially the conductor of the ASTRO EcoSystem orchestra. It is a combination of Controls and Software that is highly intelligent with enhanced capabilities.

ASTROtech is the brain behind the entire solution. It is essentially the conductor of the ASTRO EcoSystem orchestra. It is a combination of Controls and Software that is highly intelligent with enhanced capabilities.

It intelligently tracks the shipments from ASTROinduct to ASTROcart, aids in moving the ASTROcart smartly on the ASTROtrack and commands the ASTROcart to drop a shipment in the correct ASTROcollect option.

MULTIPLE CHALLENGES

| INDUSTRY CHALLENGES | INDUSTRY CHALLENGES HOW ASTRO ADDRESSES IT |

|---|---|

| Existing solutions are extremely rigid and designed to cater to specific applications | ASTRO is extremely modular, scalable, flexible & comes in a variety of configurations as per client and application needs |

| Manual operations are inefficient, riddled with inaccuracies, do not provide a clear visibility and highly dependent on trained manpower | ASTRO can grow with you. It can help you start off with automation at a very small level and expand as your needs increase. Due the extremely quick ROI, you can adopt automation and avoid manual operations |

| Simpler automation solutions lack intelligence and are not dependable. They are error prone, inefficient and typically have a low throughput / sort destination matrix. Mostly importantly they cannot handle extreme load variation | ASTRO can replace the simpler automation solutions with its easy to deploy, cost effective, highly intelligent industry grade solutions. With high sorting speeds and high accuracy, these systems can easily replace existing simpler automation |

| The larger and more complex solutions are too expensive, have a long lead time & go live time. Typically they have a large foot print and need highly skilled manpower | ASTRO with its smaller footprint, quick deployment, ease of use, simple intuitive design and a variable throughput / destination matrix is a clear winner. With the building blocks structure and flexible design where you use only the amount of system needed to process the packages, ASTRO has a lower operations & maintenance cost |

| Current systems have high downtime and are difficult and expensive to maintain | ASTRO has a minimal number of parts which are very easy to replace and the modular structure means even in extreme cases, the entire system is never down – a system would only be down partially. This leads reduced maintenance headaches |

MULTIPLE INDUSTRIES AND APPLICATIONS

- E-commerce

- Courier, Express, Parcel

- 3PL & Logistics

- Warehousing

- Retail, Fashion & D2C Brands

- Pharma & Chemicals

- Automotive

- FMCG

- Food & Beverages

- Quick Commerce

- Micro-Fulfillment Solutions

- E-Commerce Operations

- Order Consolidation / Order Fulfillment

- Store Replenishment

- Pharmaceutical / Retail Fulfillment

- 3rd Party Logistics and Fulfillment

- Postal and Parcel Sortation

- Package Putaway & Picking

- Inbound Package Sortation

- Returns Sortation

- Direct Bagging

Join the future

of logistics today.