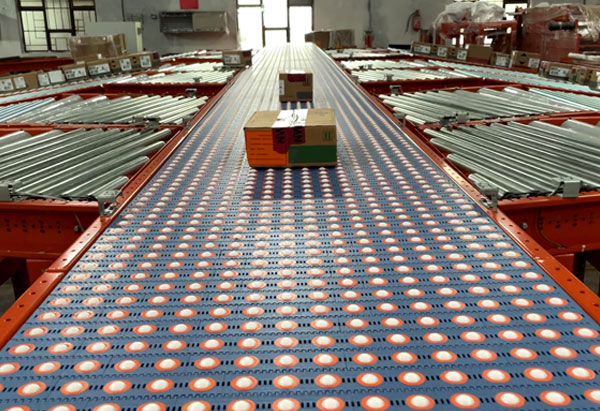

SORTATION SYSTEM

Nido Automation designs, develops and manufactures a comprehensive line of sortation systems for diverse range of products, capable of sorting with great throughput and precision. With our in-house team of control engineers and software professionals, we are able to provide a tailor-made solution just as you need.

Our DENEB Sortation solutions automate the processing and sorting system in your distribution center starting from the receipt of good till sorting and dispatching, preventing wastage of time, materials and your valuable resources.

Our one stop sorting solution are designed to turbo charge your sorting process from start to finish with great accuracy and throughput.