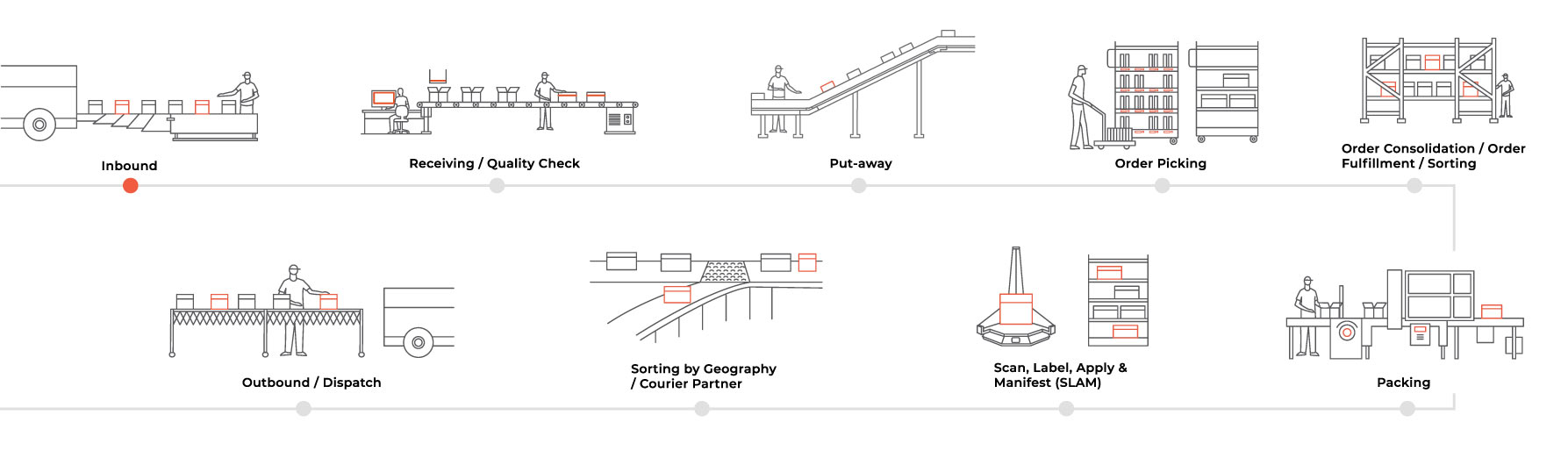

Sorting by Geography / Courier Partner

A range of automation solutions to organize and categorize items based on geography,

courier partner or specific criteria, making it easier to locate, pick, pack, and ship products.

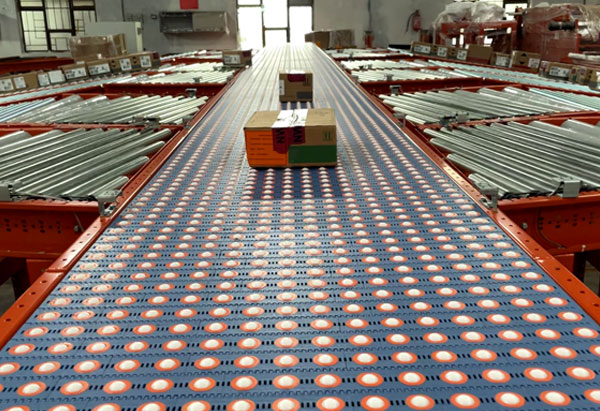

A sortation system in a warehouse is a critical component of the order fulfillment process. It involves the use of technology and conveyor systems to efficiently sort and direct items to their designated locations within the facility. The primary goal is to streamline the shipping process, reduce errors, and enhance overall operational efficiency.

There are different techniques to sort the items like sorting by electric arm, steerable wheel, sliding shoe, cross belt and others. Once the items are unloaded, they go through scanning and based on the scanned data, they are sorted to different destinations.

At NIDO, we offer a wide range of sorting solutions to unload, sort, pack and reload the items. Our automation solutions for sorting will help you in

- Reducing the storage dependency by directly loading the unloaded items

- Scanning and sorting of items with 100 percent accuracy

- Different sorting mechanisms depending on your application and product types

- Customized software solutions to automate the data storage and transfer process.