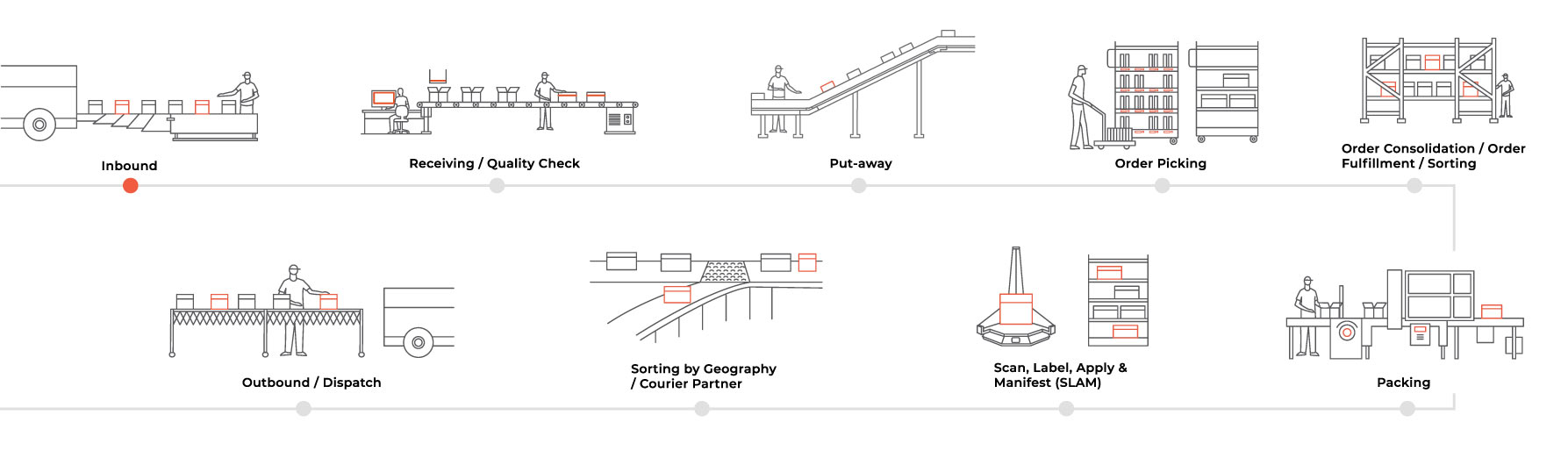

Inbound

A range of unloading automation solutions to ensure efficiency, accuracy, and the safe handling of incoming products.

AUTOMATIC LOADING UNLOADING SOLUTIONS

Automatic loading unloading can speedup the process, reduce labour cost, minimize product damage and streamline the entire logistics and supply chain process.

A typical manual loading unloading process by forklift may take around 30-45 minutes, labour scarcity might be a major hurdle specially during the pandemic. Nido’s automatic loading and unloading solutions can do it in 5-10 minutes with great efficiency and accuracy. The time gap between unloading a trailer and transporting the materials inside the warehouse can be cut to a great extent.

- Proper handling of products, no product damages

- Quick turnaround time, use of less trailer/container.

- Increased safety, no use of forklifts, proper ergonomics.

- A variety of add-ons – barcode scanning, counting, weighing, dimensioning etc.

- Increased dock efficiency, Each dock can handle high volumes.

Revolutionize Your Warehouse Inbound Process Today!

Unlock Efficiency, Reduce Costs, and Boost Productivity. Upgrade to Our

State-of-the-Art Unloading Solutions.