ROLLER CONVEYOR

Our CANOPUS roller conveyors can help transport boxes, crates, totes, pallets and polybags providing a fully automated material movement system in your warehouse or fulfillment centers. It can be configures to work with bends, gates and turn tables.

The material of the CANOPUS roller conveyor can be stainless steel, mild steel, plastic coated or galvanized depending on your requirements. Our roller conveyors can be used in logistics, manufacturing, food processing, e-commerce, automotive and FMCG industries to transport materials.

- The hardware and software can be customized as per your application.

- Powered or gravity roller conveyor option available.

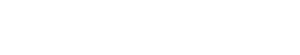

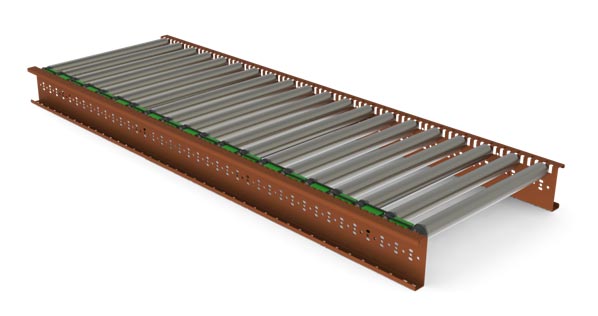

1. Gravity Roller Conveyor

The Gravity roller conveyor is used for the transport of material either manually or via gravity down a slope. This type of conveyors generally used for assembly and picking line.

| Technical Specifications | ||

|---|---|---|

| General technical data | Max. load capacity | 100 kg/m |

| Ambient temperature | 0 to +40 °C | |

| Incline/ Decline | Suitable for decline up to 70 to 100 | |

| Roller | Roller type | Interroll Series 1100 and Interroll Series 1700 |

| Roller Diameter | 50 mm | |

| Roller Material | Zinc Plated Steel, PVC | |

2. Motorized Roller Conveyor

The DC roller conveyor allows zero pressure accumulation transport of unit loads by means of a controller.

Each zone is driven by a Roller Drive EC5000 that is connected to a fixed number of slave rollers via Poly Vee belts.

| Technical Specifications | ||

|---|---|---|

| General technical data | Max. load capacity | 50 kg/m |

| Conveyor speed | 0.1 to 1 m/s | |

| Ambient temperature | 0 to +40 °C | |

| Roller | Roller Type | Interroll Series 3500 |

| Roller Diameter | 50 mm | |

| Roller Material | Steel 1.5 mm, zinc-plated | |

| Drive | Rated voltage | 24/48 V |

| Motor Type | Interroll Roller Drive EC5000 | |

| Electrical power | 50 W | |

| Transmission Medium | Poly Vee Belt | |

| Torque Transmission | Roller to Roller | |

3. Curve Roller Conveyor

The DC roller curve conveyor changes the direction conveying goods. The tapered rollers retain the alignment of the conveying goods between the side frames. A control system enables zero pressure accumulation transport. Each zone is driven by a DC Roller Drive that is connected by poly V belts through poly V pulleys connected at the end of each roller. These conveyors are available in 30°, 45°, 60°, and 90°.

| Technical Specifications | ||

|---|---|---|

| General technical data | Max. load capacity | 50 kg/m |

| Conveyor speed | 0.1 to 1 m/s | |

| Ambient temperature | 0 to +40 °C | |

| Roller | Tapered Roller | Interroll Series 3500KXO |

| Roller Material | Steel 1.5 mm, with gray tapered polypropylene sleeves | |

| Number of roller | 6 for 30°, 9 for 45°, 12 for 60°, 18 for 90° | |

| Drive | Rated voltage | 24/48 V |

| Motor Type | Interroll Roller Drive EC5000 | |

| Electrical power | 20 W, 35 W, 50 W | |

| Transmission Medium | Poly Vee Belt | |

| Torque Transmission | Roller to Roller | |

4. Roller Merge Conveyor

The merge is used for connecting lateral roller tracks at an angle (30° or 45°) to the main track.

This can be used for moving material off the track (e.g. with HPD (High Performance Divert)) or onto the track.

| Technical Specifications | ||

|---|---|---|

| General technical data | Max. load capacity | 50 kg/m |

| Conveyor speed | 0.1 to 1 m/s | |

| Ambient temperature | 0 to +40 °C | |

| Roller | Roller Type | Interroll Series 3500 |

| Roller Diameter | 50 mm | |

| Roller Material | Steel 1.5 mm, zinc-plated | |

| Drive | Rated voltage | 24/48 V |

| Motor Type | Interroll Roller Drive EC5000 | |

| Electrical power | 50 W | |

| Transmission Link | Poly Vee Belt | |

| Torque Transmission | Roller to Roller | |